- Professional Qualifications

-

-

Electroplating Technician, Special Grade

1 person -

Electroplating Technician 1st Grade

1 person -

Electroplating Technician 2nd Grade

4 person

-

Responsible for handling poisonous and deleterious substances

3 person -

Hazard Prevention Manager

1 person -

Forklift skills training

5 person

-

ABOUT DENTO JAPAN

“Plating”

a service industry

Do the “plating” as you are asked. That is a very important thing.

However, depending on the shape, purpose, and material, there may be a process that is more suitable than the requested processing type and film thickness instructions.

We, as a plating company, can offer suggestions for your manufacturing concerns, such as dimensions for thick plating, and whether or not to polish before plating.

A higher level of manufacturing

Surface treatment can increase the value of a product. For example, by plating aluminum materials, it is possible to add electric current-carrying properties, or by partial plating, it is possible to increase the hardness of specific parts.

We focus on joint development with chemical companies and quality control, and can provide consistent services from trial production and development to mass production and product inspection. In order to provide stable surface treatment services, we thoroughly manage daily concentration and film thickness control.

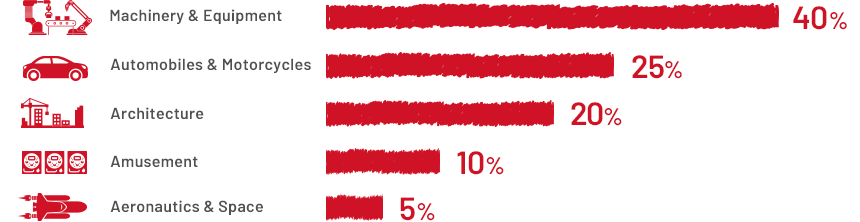

FIELDS OF PROCESSING

Flexible response by utilizing the network

At our company, we are able to solve problems without stress by utilizing our network. Our company is divided into three departments, and we keep close contact with each other so that we can manage deadlines and respond to customers’ requests smoothly.

In addition, we have a system in place to propose solutions to various problems by cooperating with partner companies, even if it is difficult to do so within the company alone.

DEPARTMENT

In order to respond to various needs, we have established three departments: General Affairs Department, Manufacturing Department, and Business Development Department.

NETWORK

Solving problems by utilizing the network. “By using a network of plating companies, we are able to solve various problems by utilizing the characteristics of each company.

-

zinc platingZn

A surface treatment process that imparts the functions and characteristics of zinc by depositing zinc on the surface of products and parts.

-

Chemical polishCP

Chemical polishing (CP) can remove contamination (abrasive) that cannot be removed by precision cleaning (SMC).

-

Electrolytic Nickel

Electroless NickelNi/

Ni-PPlating with excellent corrosion resistance and chemical resistance, good physical properties such as hardness and flexibility, resistance to discoloration, and good direct adhesion.

-

Tin Plating

Matte SilverSn/AgTin is a silvery white metal with distinctive properties. It has a very low melting point and is suitable for soldering in alloys with other metals.

-

Hard chrome platingHCr

It has been applied thinly over copper and nickel plating for a long time, and is widely used in miscellaneous goods and automotive parts.

-

Copper platingCu

Plating in which the object to be plated is placed in a plating bath in which copper is melted, and the copper plating film is applied to the object using electricity.

-

Plating on stainless steel

High corrosion resistance is achieved by forming a chromium oxide film (passivation film) on the top surface.

-

Plating on aluminum

Alkaline etching solution and zincate solution are available, which are expected to cover the initial degreasing in the process.

-

Plating on titanium

The general hardness of pure titanium is 100 to 150, but by nitriding or carbonizing the surface, the hardness can be dramatically increased.

-

Decorative plating

After copper and nickel plating, a thin chrome plating of about 0.3 µm is applied to the surface layer.

Equipment and inspection environment

Automatic lines

We have two lines, rack and barrel, for various types of chromate zinc plating. Both lines are automated and can handle small to large items from single prototypes to mass production.

Large products up to 1800mm in length and 200kg in weight can also be produced using automated machines. The automation reduces the variation of the finished product and provides a stable and high quality product.

小We are also good at handling small products. We can handle small items with a minimum diameter of 0.9mm and lightweight items weighing as little as 1g each. We can provide stable quality by changing the barrel selection and plating conditions according to the shape and quantity.

Manual line

For functional plating such as tin and electroless nickel, we are able to provide detailed quality control and flexibility in accordance with the material, which only a manual line can provide. We can also handle requests for partial plating by masking, base plating, and treatment of difficult-to-plate materials such as aluminum, etc. Taking advantage of our flexibility, we can handle everything from the development stage to trial production and mass production.

Inspection environment

After plating, inspections are conducted before shipment. In addition to visual inspections, we have an environment that allows us to perform thorough quality control in-house, including precision inspections using film thickness measuring instruments. In addition, in order to provide a stable plating service, we regularly check the concentration of the processing solution and record the results, so that if a problem should occur, we can determine the cause and take countermeasures.

Environmental Equipment

Environmental measures are the duty of companies that support the future. We have installed an automatic drainage system to detoxify wastewater unattended. In addition, we have installed a 24-hour monitoring system, and we will continue our efforts to create a better environment for the future.

Company Profile

-

NameDENTO Japan Ind Co.,Ltd.

-

Address

1-25-8 Tasumikita, Ikuno-ku, Osaka City 544-0004

-

CEORyoichi Terauchi

-

Phone+81 6 67 51 61 94

-

Fax+81 6 67 51 62 38

-

FoundedIn 1967

-

EstablishmentMay 2003

-

Business contentsSurface treatment business complete set